customer service

24/7 available service

global shipping

fast,reliable and door step delivery

100% Money Back

If the item didn't suit you

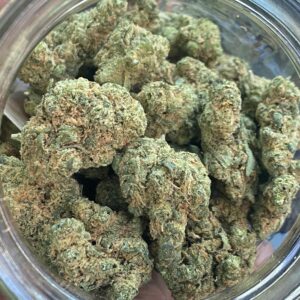

Variety of cannabis indica,sativa, hybrid available

We currently offer a diverse range of indica, sativa, and hybrid strains in stock. Place your order now to secure your preferred choice."

variety of vape carts available

We are pleased to offer a wide variety of vape cartridges in stock, including DMT carts, CBD carts, and mushroom vapes. Explore our selection today

variety of edible available

We offer a wide variety of edibles, including chocolate bars, beverages, cookies, and much more. Explore our selection today

Featured Products

We provide top-notch quality in our shop

- cannabis sativa

Amnesia Haze

Rated 0 out of 5$140.00 – $1,500.00Clear1 POUND1/16 POUND1/2 OZ1/2 POUND1/4 POUND1/8 POUNDAN OZ - Edible

burst Sour Blue Razz Live Rosin Gummies – 200mg

Rated 0 out of 5$130.00 – $650.00Clear12162048 - cannabis sativa

Chocolope strain

Rated 0 out of 5$100.00 – $1,500.00Clear1 POUND1/16 POUND1/2 OZ1/2 POUND1/4 POUND1/8 POUNDAN OZ - cannabis sativa

Green Crack

Rated 0 out of 5$150.00 – $1,500.00Clear1 POUND1/16 POUND1/2 OZ1/2 POUND1/4 POUND1/8 POUNDAN OZ - cannabis sativa

Jack Herer

Rated 0 out of 5$135.00 – $1,500.00Clear1 POUND1/16 POUND1/2 OZ1/2 POUND1/4 POUND1/8 POUNDAN OZ - cannabis indica

Smackers Infused Mexican Candy Edibles

Rated 0 out of 5$100.00 – $500.00Clear12162048 - cannabis sativa

Super Silver Haze

Rated 0 out of 5$140.00 – $1,500.00Clear1 POUND1/16 POUND1/2 OZ1/2 POUND1/4 POUND1/8 POUNDAN OZ

Need help in choosing the right product.

California stands at the forefront of the cannabis industry, boasting a myriad of dispensaries that cater to every cannabis enthusiast’s needs. From San Francisco to Los Angeles and everywhere in between, the Golden State is home to some of the best cannabis shops in the world. Here, cali-bud shop stands as one of the top establishments that epitomize excellence in product quality, customer service, and overall experience.

Outstanding online weed shop! Seamless ordering, prompt customer service, and discreet packaging. The product was fresh, potent, and accurately described. Highly recommended for premium-quality weed and excellent service. Will definitely return.

Testimonials

Here are some reviews we’ve gathered from our customers

Overall, I’m quite satisfied with my experience shopping at this online weed store. The prices are reasonable, especially considering the quality of the products. However, I do wish they offered more discounts or promotions for loyal customers. While they do have occasional sales, I believe implementing a rewards program or offering discounts for bulk purchases would greatly enhance the shopping experience and encourage customer loyalty. Nevertheless, I appreciate the variety of products available and the convenience of shopping online.

sean micheal Jones

Fantastic experience with this online weed shop! Smooth ordering process, quick customer support, and discreet packaging. The product quality exceeded expectations, delivering freshness, potency, and accurate descriptions. Highly recommended for top-tier weed and stellar service. I’ll be coming back for more!

George freeman

customer

Thrilled with my purchase from this online weed shop! Not only was the product top-notch, but the package arrived right on time, as promised. The timely delivery, combined with the excellent product quality, makes this shop a standout choice. Highly recommend for anyone looking for reliable service and premium weed. Will definitely be ordering again.

Briana Luke

cali bud

cali-budshop Dispensary: The Best Weed Dispensary in the USA Right Now

When it comes to top-tier cannabis, there’s no better place to shop than cali bud shop Dispensary. Whether you’re a seasoned cannabis enthusiast or someone seeking a reliable dispensary to buy marijuana, Cali-Budshop stands out as the best in the business. Known for its exceptional weed quality, premium products, and excellent customer service, Cali-Budshop has earned its place as one of the finest dispensaries in the United States.cali bud

The Best cali kush at Cali-Budshop Dispensary

One of the primary reasons Cali-Budshop has become the go-to dispensary is its unparalleled weed quality. Their products are carefully cultivated, and only the best marijuana strains make it to the shelves. Whether you’re looking for cali kush or top-tier concentrates, Cali-Budshop ensures that every item meets rigorous standards, delivering a consistent and potent experience.cali bud

Every product undergoes thorough testing, ensuring that customers receive the highest quality marijuana with each purchase. Whether you’re buying flower, edibles, or extracts, you’ll find that Cali-Budshop is dedicated to offering only the finest cannabis products available. If you’re someone who values quality, Cali-Budshop Dispensary is the place to go.cali bud

Best Customer Service in the Cannabis Industry

At Cali-Budshop, customer satisfaction is the top priority. The knowledgeable and friendly staff are always ready to assist, whether you need help choosing the perfect strain or have questions about products. They take the time to ensure that every customer feels welcomed and informed, making each visit a pleasant experience.

Not only do they offer helpful advice and recommendations, but their team also provides personalized consultations, making sure you get exactly what you’re looking for. If you need expert guidance on buying cannabis online or understanding the differences between various strains, the customer service at Cali-Budshop is second to none.

Affordable Cannabis Products without Compromising Quality

Cali-Budshop understands that the price of cannabis is an important factor for many customers, which is why they offer affordable products without sacrificing quality. With a wide range of pricing options, customers can find the perfect product that fits their budget. Whether you’re on a tight budget or looking to splurge on premium items, Cali-Budshop has something for everyone.cali bud

Their pricing is transparent, and you’ll find that Cali-Budshop offers excellent value for the quality you get. With regular discounts and promotions, you can expect the best prices for premium marijuana.

Premium Products for the Connoisseur

Cali-Budshop isn’t just about affordability; they also cater to those seeking premium cannabis products. Whether you’re looking for exotic strains, limited-edition cannabis, or luxury marijuana items, you can trust Cali-Budshop to provide the finest options. They stock a variety of premium flowers, luxury concentrates, and top-shelf edibles, ensuring that even the most discerning cannabis connoisseurs find something they’ll love.cali bud.

Cali-Budshop’s premium cannabis comes with rich, flavorful experiences that elevate your smoking or vaping experience. For those who want to indulge in the best of the best, Cali-Budshop offers unparalleled luxury marijuana products.cali bud.WE HAVE OTHER PRODUCT CATEGORY SUCH AS CANNABIS INDICA,CANNABIS SATIVA, CANNABIS HYBRID, PREROLL JOINT, VAPE CARTS , CONCERNTRATE.

On-Time Delivery, Every Time

When it comes to on-time delivery, Cali-Budshop goes above and beyond to ensure that your order arrives when you need it. Their delivery services are fast, reliable, and discreet. Whether you’re in a major city or a more remote area, Cali-Budshop ensures that your ganja online purchase will arrive on time, every time.

Their quick delivery system allows you to order your weed online and have it delivered directly to your door, ensuring that your cannabis arrives fresh and safe. With on-time deliveries, you can enjoy your products without waiting long.

buying cannabis online

In today’s fast-paced world, convenience is key, and Cali-Budshop makes it easier than ever to buying cannabis online. The website is user-friendly, making it simple to browse their extensive selection of marijuana products and place your order. Whether you’re looking to buy cannabis online or searching for a nearby weed store dispensary, Cali-Budshop has you covered.

You can find everything from flower and pre-rolls to edibles, topicals, and more—all available for easy ganja online purchase. Plus, their streamlined checkout process ensures you’ll receive your order in a timely manner.

cali flower

Cannabis Clubs Near me

Cali-Budshop also partners with local cannabis clubs, offering memberships to those who want to enjoy cannabis in a social setting. If you’re asking yourself, “cannabis clubs near me,” Cali-Budshop has a range of affiliated clubs that cater to members in select regions. It’s a great way to connect with like-minded people and enjoy cannabis in a safe and welcoming space.get the best cali flower at cali-budshop

buying marijuana online,

If you’re looking to buying marijuana online, look no further than Cali-Budshop. They offer an extensive range of marijuana for sale, catering to both medical and recreational users. Whether you’re looking to buy cannabis for medical use or simply enjoy some premium flower, Cali-Budshop makes it easy to find what you need.cali bud

Medical Marijuana Doctor Near me

For those who need medical marijuana, Cali-Budshop provides easy access to medical marijuana doctors. With cheap consultations and expert guidance, you can quickly and affordably find out if medical cannabis is right for you. Their doctors are friendly, knowledgeable, and ready to help you navigate the process of obtaining a medical marijuana prescription.

Weed Store Dispensary Near me

If you’re searching for a weed store dispensary near me, Cali-Budshop is the ultimate destination. With a vast selection of cannabis products and an unwavering commitment to quality and customer service, they are a top choice for cannabis users across the USA. Whether you’re looking to pick up a few items or explore their entire catalog of cannabis goods, Cali-Budshop provides an excellent dispensary experience.cali bud

Conclusion: Why Cali-Budshop is the Best Dispensary in the USA

Cali-Budshop is the perfect place for anyone looking for premium cannabis, exceptional customer service, and a convenient online shopping experience. Their commitment to quality, affordability, and timely delivery makes them a standout in the crowded cannabis market. Whether you’re a seasoned enthusiast or just starting to explore the world of marijuana, Cali-Budshop is the best dispensary in the USA at the moment.

With the ability to buy cannabis online, browse their wide range of products, and enjoy excellent customer service, it’s no wonder why Cali-Budshop has earned its reputation as one of the leading dispensaries in the United States. Don’t miss out—visit Cali-Budshop Dispensary today and experience the best in cannabis!.cali bud